Selecting and sizing a condensate pump can be tricky with a few key variables to consider. Our experts at BFS Industries are here to break down some of those variables and offer some condensate pump sizing recommendations.

Measurements Needed to Size a Condensate Pump:

- 1. Flow

- 2. Pressure Required

- a) Vertical height difference

- b) Friction head loss

- c) Destination backpressure

- 3. Net Positive Suction Head (NPSH)

1. Flow

The first thing to consider is the amount of condensate your steam system is generating. As a good rule of thumb, you should size your condensate return pump for 2-3 times your condensate rate. For example, if your system generates 10,000 #/hr of condensate (20 GPM), you should select a pump that can flow 40-60 GPM. Selecting a condensate pump that is 2-3 times your condensate rate will ensure that your pump is not short cycling and that the system can absorb any surges in your condensate rate.

2. Pressure Required

Another factor to consider is how much pressure is required to return your condensate back to where it needs to go. This can be challenging with piping that snakes through buildings and systems located on different floors.

Let’s break the required pressure into a few main categories:

a) Vertical height difference: This is measured from where you are pumping from to where you are pumping to. For example, if you pump from a condensate system mounted on the floor in the basement to another tank located on the floor above, you might be looking at a vertical height difference of 30 feet that needs to be accounted for.

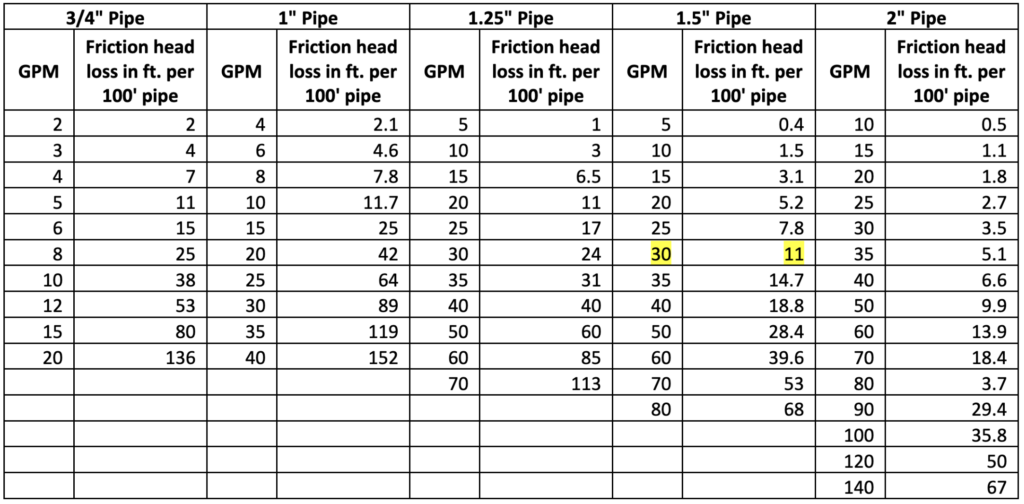

b) Friction head loss in piping: This is usually the trickiest part to calculate. Friction loss in pipes depends on pipe size and the flow rate through the pipe. The more flow through the pipe, the higher the friction is going to be per unit length.

For this example, let’s assume we’re sending 30 GPM of water through a 1.5-inch pipe. 30 GPM going through a 1.5-inch pipe will see a friction head loss of 11 feet per 100 feet of piping (see chart below). If the water must travel through 75 feet of piping, this will be equal to 8.25 feet of friction head loss.

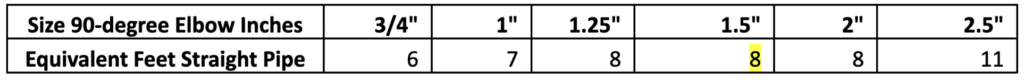

We must then account for 90-degree elbows in our piping. Each size elbow has an equivalent length of pipe per the chart below. If our 1.5-inch piping has six elbows, then it would be equivalent to 48 feet of straight 1.5-inch piping, which equates to 5.28 feet friction loss.

c) Destination backpressure: If you return your condensate to an atmospherically vented receiver, then this value will be 0. But under some circumstances, you may be returning condensate to a pressurized vessel. Most deaerators operate at 5 PSIG, and we must overcome this 5 PSIG pressure to get the condensate back into the DA tank.

To figure out the total required pump discharge pressure, we must add the values from categories a, b, and c.

From this example, we have a 30-foot vertical height difference, 8.25 feet of pipe loss and 5.28 feet of elbow fitting loss, and, lastly, we are pumping back to a deaerator operating at 5 PSIG, which is equivalent to 5 PSIG x 2.31 = 11.55 feet.

30’+8.25’+5.28’+11.55’= 55’ TDH pump discharge pressure required, or 23.8 PSIG.

At this pressure, we would usually round up to an even 30 PSIG discharge to account for any errors in our calculations or assumptions. It is better to have too much pressure than too little.

3. Net Positive Suction Head (NPSH)

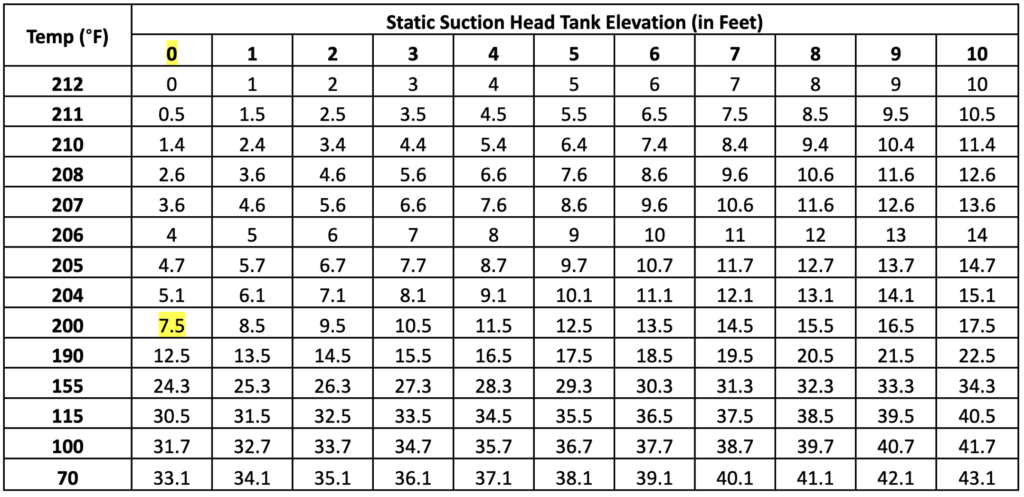

In general, the higher the flow rate of the pump, the more Net Positive Suction Head (NPSH) the pump is going to require. In the simplest form, NPSH available is based on water temperature and source tank elevation. For each foot of tank elevation, you gain one foot of NPSH available due to the static head. The cooler the temperature of the condensate, the more NPSH you have available, which is also due to atmospheric pressure.

There are two main types of condensate systems: those where the tank is sitting on the floor with the pump attached directly to the side, and those where the tank is mounted on a stand and the pumps are piped underneath. Depending on your pump NPSH required, you can select which style of tank will work for your chosen pump. Below is a chart representing NPSH available for different tank elevations and temperatures.

If your tank is mounted on the floor, we would use the “0” column of the chart. If we assume the tank temperature is 200° F, that would mean we have 7.5 feet of static suction head available due to atmospheric pressure. As long as our selected pump has a NPSH less than 7.5 feet, we can use a floor mounted receiver for this application. If the condensate is hotter or the pump requires more NPSH, we may have to go with a stand mounted system.

We Can Help

At BFS Industries, we specialize in customizing condensate pump systems to meet your specific needs. Contact us today to get a quote and design on a condensate return system or condensate pump.